Quality of fuel is essential to the efficiency and performance of engines. Diesel fuel, with time will be contaminated with contaminants like water and sediment. This could cause engine malfunctions and require costly repairs. Polishing of fuel is an option to reduce the risk of contamination with fuel and ensure the smooth operation of engines.

Fuel polishing, also known as diesel fuel polishing is a process that involves the removal of impurities and contaminants from diesel fuel. The process of polishing fuel is offered by experts who use the most advanced technology and equipment to restore fuel to its original form. Polishing your fuel can improve the efficiency of your engine and lowers maintenance costs by eliminating harmful substances.

Numerous polishing services for fuel are available to cater to the diverse needs of industries that rely on diesel fuel. They are run by highly-trained technicians with expertise in fuel systems who comprehend the complexity of fuel contamination. They can spot fuel problems using their specialized equipment and deep knowledge.

The purpose of fuel polishing is to eliminate water and sediment, sludge and microbial contaminants from diesel fuel. The accumulation of water in fuel tanks could be triggered by condensation or leaks, which causes corrosion, degrading fuel and the development and spread of mold and bacteria. Sludge and sediment may be caused by impurities within the fuel or gradual degradation of the fuel components. These pollutants can clog the injectors and filters as well as other important components. This could result in an impairment in the performance of engines or even a failure.

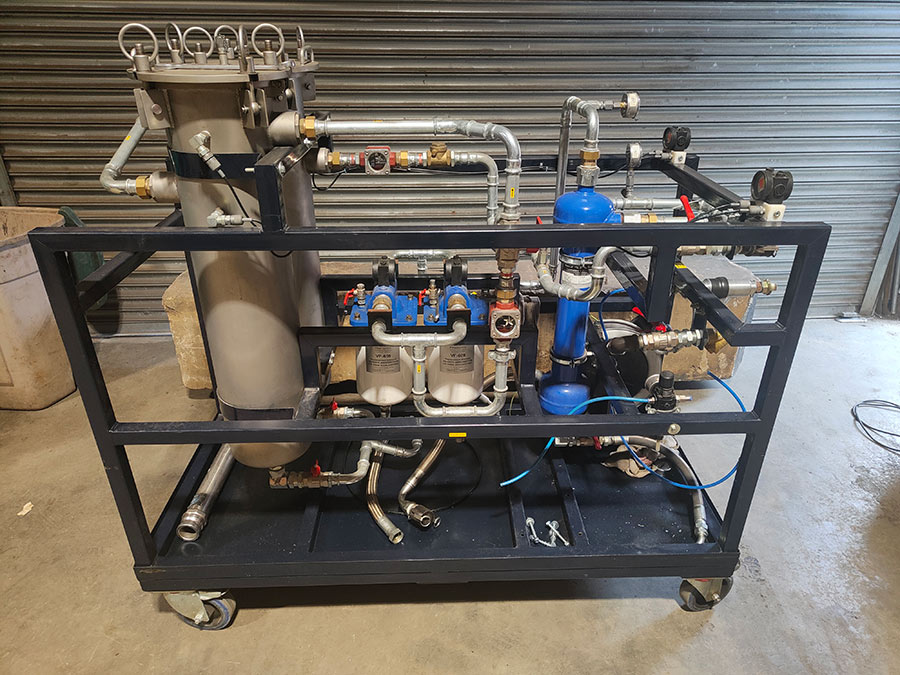

Diesel polishing typically involves a multi-step process. Analysis and sampling of fuel is the initial step to identify the degree of contamination. Technicians use filters to eliminate the contaminants. These systems utilize various technologies and filter media to efficiently remove pollutants from fuel, leaving clean and pure diesel.

Regular fuel polishing offers several key benefits. It improves the quality of the fuel and ensures that engines get clean, consistent fuel to allow for optimal combustion. Additionally, it improves fuel efficiency as well as performance. This is a result of reduced emissions and savings in cost. Polishing the fuel also decreases the chance of engine breakdowns and damages caused by gasoline that is contaminated. Removal of harmful substances can help maintain engine integrity, extending their life and reducing repairs.

Polishing diesel is a common procedure that provides many benefits to keep the fuel quality. First, it assists in remove water, sediment, and microbial contaminations that could hinder the performance of engines. By eliminating these impurities through the process of diesel polishing, the quality of fuel is drastically enhanced. This, in turn, enhances combustion efficiency, resulting in an increase in fuel economy and decreased emissions. Regular polishing of the diesel engine also stops the fuel filter from becoming blocked, injections, and many other essential components. This reduces the chance of engine damage, or expensive repairs. Regularly polishing fuel makes sure that the fuel storage systems last longer as they prevent the buildup of corrosion and sludge. Regular polishing of diesel engines or fuel cleaning can boost the performance of engines and lower cost. It also increases the reliability of equipment.

The services offered by fuel polishing are tailored to the requirements of specific industries and applications. From backup generators to vessels in the marine sector to construction equipment and transport fleets, fuel polishing is a variety of solutions to deal with the contamination of fuel in a wide spectrum of sectors. This is particularly important for industries that depend on a reliable, uninterrupted power supply as and those operating in remote or harsh environments.

In essence, polishing fuel is an essential process that helps ensure the purity and purity of diesel fuel. The removal of contaminants and impure substances improves engine performance and lowers the cost of maintenance. By investing in professional polishing their fuel, companies can safeguard their operations, improve performance and lessen the risk associated with fuel contamination. Fuel polishing can unlock the power of diesel fuel, allowing you to drive your business ahead.